Electric cars are becoming more popular, and with that comes a need to understand how they actually work, especially their motors. Unlike traditional vehicles that use combustion engines, electric cars rely on electric motors to convert stored electrical energy into motion. This article aims to break down the mechanics behind electric car motors, offering insights into their components, types, and how they power vehicles. So, let’s explore how does an electric car motor work and what makes it tick.

Key Takeaways

- Electric motors use electromagnetism to convert electrical energy into mechanical energy.

- The main parts of an electric motor are the stator, rotor, and bearings, which work together to create motion.

- There are different types of electric motors, including DC and AC motors, each with its own applications.

- Electric vehicles utilise batteries and inverters to power their motors efficiently, including regenerative braking systems.

- The future of electric motor technology looks promising with advancements in design and battery technology, potentially enhancing performance and range.

Understanding Electric Motors

Electric motors are at the heart of every electric vehicle (EV), converting electrical energy into mechanical energy to propel the car forward. They represent a significant departure from traditional internal combustion engines (ICEs), offering a different approach to generating motion. Let’s take a look at how they work.

The Principle of an Electric Motor

Electric motors operate on the fundamental principle of electromagnetism. When an electric current passes through a wire, it creates a magnetic field. If you place this wire within another magnetic field, the two fields will interact, producing a force that causes the wire to move. In a motor, this movement is harnessed to rotate a shaft, which then drives the wheels of the vehicle. The electric car’s motor is built around converting electricity into mechanical energy through the creation of a magnetic field.

How Electric Motors Differ from Engines

Engines and motors both convert energy into motion, but they do so in fundamentally different ways. Engines, like those found in petrol or diesel cars, rely on the combustion of fuel to generate energy. This combustion process creates heat and pressure, which is then used to move pistons and turn a crankshaft. Electric motors, on the other hand, use electromagnetic forces to directly generate motion. This difference has several important implications:

- Electric motors are generally more efficient than engines, converting a higher percentage of input energy into useful work.

- Electric motors produce zero tailpipe emissions, contributing to cleaner air in urban areas.

- Electric motors are typically quieter than engines, resulting in a more refined driving experience.

Electric motors offer instant torque, meaning they can deliver maximum power from a standstill. This gives EVs their characteristic rapid acceleration.

The Role of Electromagnetism

Electromagnetism is the driving force behind electric motors. The interaction between magnetic fields is what causes the rotor (the rotating part of the motor) to spin. The strength of these magnetic fields, and the way they are arranged, determines the power and efficiency of the motor. The stator uses energy to create a magnetic field that then turns the rotor. Modern electric motors use sophisticated designs and materials to maximise the electromagnetic forces at play, resulting in high-performance and efficient propulsion systems.

Key Components of Electric Car Motors

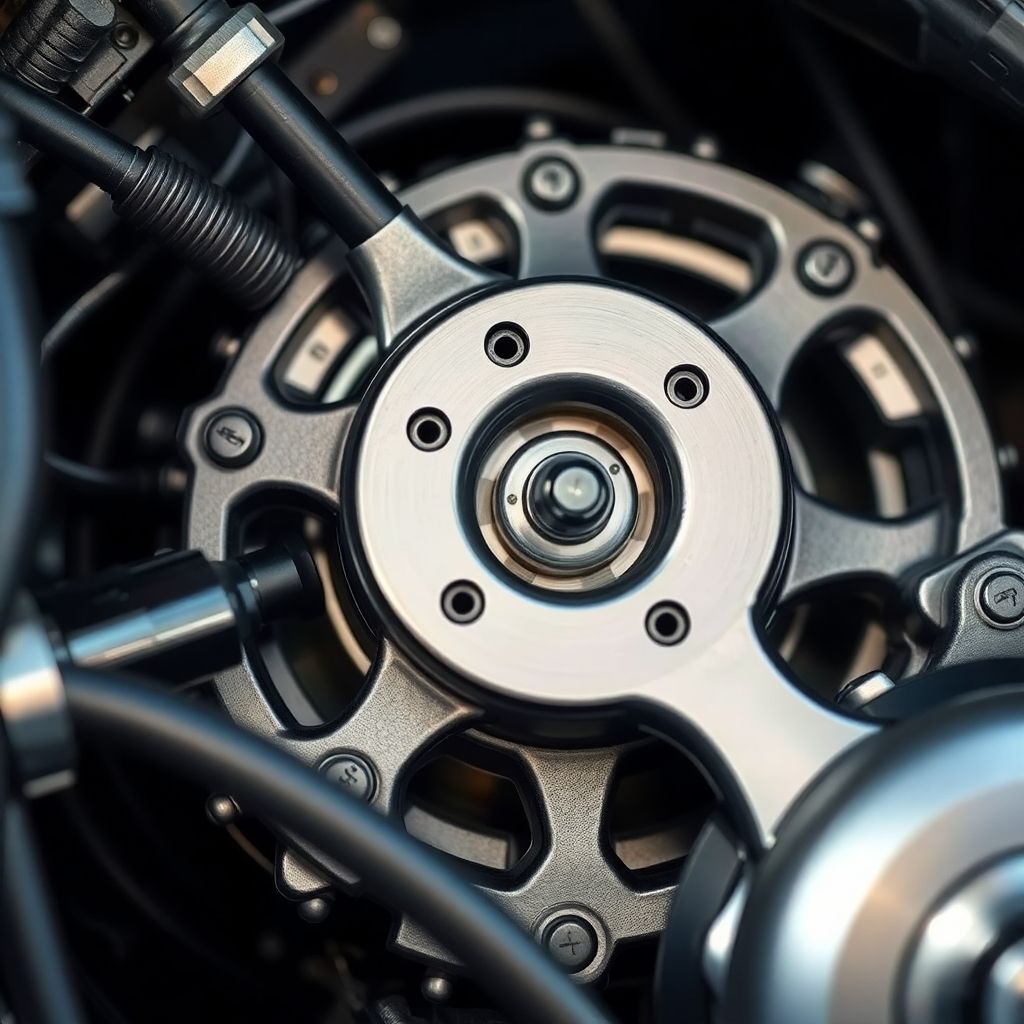

The Stator and Rotor Explained

Okay, so when you look at an electric car motor, you’ll hear a lot about the stator and the rotor. Think of the stator as the bit that stays still. It’s got coils of wire inside, and when electricity flows through them, it creates a magnetic field. This magnetic field then interacts with the rotor, which does move. The rotor is connected to the wheels, so as it spins, the car moves. Different designs exist, some using magnets in the rotor, others using coils. The interaction between these two is what makes the whole thing work.

Importance of Bearings

Bearings are actually pretty important, even though they’re not the flashiest part. They’re all about reducing friction. Imagine trying to spin something if it’s rubbing against another surface – it’s hard work, right? Bearings allow the rotor to spin smoothly with as little energy loss as possible. This improves the motor’s efficiency and also helps it last longer. Without good bearings, the motor would wear out much faster. They support the shafts and ensure minimal energy loss, improving the motor’s efficiency and longevity.

Thermal Cooling Systems

Electric motors generate a fair bit of heat when they’re working hard. If that heat isn’t managed, it can damage the motor. That’s where thermal cooling systems come in. They’re designed to keep the motor at the right temperature. These systems drastically increase the lifespan and reliability of EV motors by dissipating excess heat. This might involve using a liquid coolant that circulates around the motor, or it could be as simple as a fan that blows air over it. Either way, it’s a vital part of keeping the motor running smoothly and preventing it from overheating.

Keeping the motor cool is super important. Overheating can lead to a drop in performance, or even complete failure. The cooling system is there to make sure the motor stays within its optimal temperature range, no matter how hard you’re pushing the car.

Types of Electric Motors

Electric cars use different types of motors to convert electrical energy into motion. Each type has its own strengths and weaknesses, making them suitable for different applications. Let’s have a look at the main types you’ll find in the world of EVs.

Direct Current (DC) Motors

DC motors are pretty basic in their operation. They connect directly to a power source, and the speed of rotation is directly linked to the current’s intensity. While they’re easy to make, they often don’t meet the requirements for power, reliability, or size needed in an EV. You might find them powering smaller things like windshield wipers or windows, but not the main drive system.

Alternating Current (AC) Motors

AC motors are more common in EVs because they can provide the necessary power and efficiency. They need a conversion circuit to transform the direct current (DC) from the battery into alternating current (AC). There are two main types of AC motors used in electric vehicles: synchronous and asynchronous motors.

Synchronous vs. Asynchronous Motors

An asynchronous motor, also known as an induction motor, uses the electric-powered stator to create a rotating magnetic field. This field pulls the rotor, making it constantly try to catch up without ever succeeding. These motors are often used in EVs that spend a lot of time driving at high speeds. On the other hand, in a synchronous motor, the rotor acts as an electromagnet, actively helping to create the magnetic field. Its rotation speed is directly related to the frequency of the current powering it. This makes synchronous motors ideal for city driving, where you’re often stopping and starting at lower speeds.

Both synchronous and asynchronous motors can work in reverse, turning mechanical energy back into electricity when you slow down. This is how regenerative braking works, similar to how an alternator functions.

Here’s a quick comparison:

| Feature | Synchronous Motors | Asynchronous Motors (Induction Motors) |

|---|---|---|

| Rotor | Electromagnet, actively creates magnetic field | Pulled by the stator’s rotating magnetic field |

| Speed Control | Directly proportional to current frequency | Relies on the ‘slip’ between stator field and rotor speed |

| Ideal Use | Urban driving, frequent stops and starts | High-speed driving over long periods |

| Regenerative Braking | Yes | Yes |

Powering an Electric Vehicle

The Role of the Battery

Electric vehicles rely on batteries, typically lithium-ion, to store the energy needed to power the motor. These batteries provide a direct current (DC) supply, which is then managed by the car’s electrical systems. The capacity of the battery directly impacts the vehicle’s range – a larger capacity means more kilometres before needing a recharge. Battery technology is constantly evolving, with ongoing research aimed at increasing energy density, improving charging times, and extending battery lifespan. It’s worth considering affordable EVs when looking at options.

Inverters and Energy Conversion

While batteries provide DC, most electric car motors use alternating current (AC). This is where the inverter comes in. The inverter’s job is to convert the DC power from the battery into AC power that the motor can use. This conversion isn’t perfectly efficient; some energy is always lost as heat. However, modern inverters are designed to minimise these losses. The inverter also plays a role in controlling the motor’s speed and torque by adjusting the frequency and voltage of the AC power it supplies. It’s a pretty important piece of kit!

Regenerative Braking Mechanism

Regenerative braking is a clever feature of electric vehicles that helps to improve efficiency. Instead of simply wasting kinetic energy as heat when braking (like in a traditional car), the electric motor acts as a generator, converting some of that kinetic energy back into electrical energy. This energy is then fed back into the battery, effectively recharging it while you slow down. This is particularly useful in stop-start traffic, where it can significantly extend the vehicle’s range. Here’s how it works:

- The driver applies the brakes.

- The motor switches to generator mode.

- Kinetic energy is converted into electrical energy.

- The battery is recharged.

Regenerative braking isn’t just about efficiency; it also reduces wear and tear on the conventional braking system, as the electric motor handles a significant portion of the braking force. This can lead to longer intervals between brake pad replacements, saving you money in the long run.

The Electric Powertrain

Integration of Motor and Power Electronics

The electric powertrain is more than just the motor; it’s a carefully orchestrated system. It integrates the electric motor with power electronics to efficiently deliver power to the wheels. This includes components like the inverter, which converts DC power from the battery into AC power for the motor, and sophisticated control systems. The inverter plays a critical role in managing the motor’s torque and speed, ensuring smooth and responsive acceleration. The powertrain also includes the DCDC converter, which transforms the battery’s DC voltage into 14V for the vehicle’s on-board network, and the on-board AC charger and C box for recharging the traction battery. The gearbox adapts the rotation speed transmitted by the electric motor to the wheels.

Control Systems for Efficiency

Electric vehicles rely on advanced control systems to maximise efficiency and range. These systems constantly monitor and adjust various parameters, such as motor speed, torque, and battery state of charge. Sophisticated algorithms optimise energy usage, ensuring that the motor operates at its most efficient point. electric engines in the limelight are now a reality. Here are some key aspects of these control systems:

- Regenerative Braking Control: Manages the amount of energy recovered during braking.

- Torque Vectoring: Distributes torque between wheels for improved handling.

- Thermal Management: Regulates the temperature of the motor and battery for optimal performance.

The control systems are not just about efficiency; they also play a vital role in safety and reliability. By continuously monitoring the system, they can detect and respond to potential issues before they become major problems.

Impact on Vehicle Performance

The electric powertrain has a profound impact on vehicle performance. Electric motors offer instant torque, resulting in quick acceleration and a responsive driving experience. The absence of a traditional gearbox means smoother power delivery and fewer moving parts, enhancing reliability. The integration of the motor and power electronics also allows for precise control over vehicle dynamics, leading to improved handling and stability. The wound rotor electric motor requires specific manufacturing processes. Here’s a comparison of traditional combustion engines and electric powertrains:

| Feature | Combustion Engine | Electric Powertrain |

|---|---|---|

| Torque Delivery | Gradual | Instant |

| Efficiency | Lower | Higher |

| Moving Parts | More | Fewer |

| Noise | Louder | Quieter |

| Maintenance | More Frequent | Less Frequent |

Advantages of Electric Motors

Efficiency and Reliability

Electric motors really shine when it comes to how well they use energy. They convert a much higher percentage of electrical energy into motion compared to petrol engines. You’re looking at figures upwards of 85% efficiency, whereas a traditional combustion engine might struggle to hit 40%. This means less wasted energy and more miles per charge. Plus, electric motors generally have fewer moving parts, which translates to less wear and tear and, hopefully, fewer trips to the garage. It’s a win-win, really.

Environmental Benefits

One of the biggest selling points of electric motors is their positive impact on the environment. Electric vehicles produce zero tailpipe emissions, which helps to improve air quality, especially in urban areas. While the production of electricity can still have environmental consequences, the potential for using renewable energy sources like solar and wind power means that electric vehicles can become even cleaner over time. It’s all about reducing our carbon footprint and creating a more sustainable future. The electric powertrain is a key component in this effort.

Cost-Effectiveness Over Time

Okay, so the initial cost of an electric car might seem a bit steep, but hear me out. Over the long haul, electric motors can actually save you money. Here’s why:

- Reduced Fuel Costs: Electricity is generally cheaper than petrol or diesel, so you’ll save money every time you “fill up”.

- Lower Maintenance: Fewer moving parts mean less maintenance. No oil changes, spark plugs, or exhaust systems to worry about.

- Government Incentives: Many governments offer tax breaks or subsidies to encourage people to switch to electric vehicles.

Electric motors offer a compelling combination of efficiency, environmental responsibility, and long-term cost savings. While there are still challenges to overcome, the advantages of electric motors are becoming increasingly clear, making them a key technology for the future of transport.

Future of Electric Motor Technology

Innovations in Motor Design

The future of electric motors is looking pretty interesting, with loads of clever ideas being thrown around. One of the big focuses is on making motors more efficient and smaller, without losing any power. Think about it: lighter cars that go further on a single charge. A big part of this involves playing around with the materials used. We’re seeing a shift towards using things like silicon carbide in power electronics, which can handle higher temperatures and voltages. This means less energy wasted as heat. Also, there’s a push to reduce our reliance on rare earth magnets. They’re great, but sourcing them can be a bit of a headache, and not very environmentally friendly. So, engineers are exploring alternative magnet designs and even motors that don’t use magnets at all.

Advancements in Battery Technology

Of course, you can’t talk about electric motors without mentioning batteries. They’re like two peas in a pod. The better the battery, the better the motor can perform. We’re seeing some serious progress here. Solid-state batteries are a big deal because they promise higher energy density, meaning more range. They’re also supposed to be safer than current lithium-ion batteries. Then there’s the whole charging infrastructure. Faster charging times are crucial. No one wants to wait hours to top up their car. So, there’s a lot of work going into developing high-power charging systems and improving the grid to handle the extra demand. regenerative braking is also improving, allowing for more efficient energy recovery.

Potential for Increased Range and Performance

All these advancements are pointing towards one thing: electric cars that can go further and perform better. Imagine electric vehicles with ranges that rival petrol cars, and acceleration that leaves sports cars in the dust. It’s not just about raw power, though. It’s also about making electric cars more practical for everyday use.

Think about things like better thermal management systems to keep the motor and battery cool, even when you’re pushing them hard. And improved control systems that optimise energy use based on driving conditions. It’s all about making the driving experience smoother, more efficient, and more enjoyable.

Here are some key areas to watch:

- Improved motor cooling techniques

- Lighter motor components

- More efficient power electronics

Wrapping Up: The Basics of Electric Car Motors

So, there you have it. Electric car motors are pretty fascinating when you break them down. They work by turning electrical energy into movement, thanks to the clever use of magnets and coils. Unlike traditional engines that burn fuel, these motors rely on electricity, making them cleaner and more efficient. Sure, there’s a lot of tech behind it, but at the end of the day, it’s all about getting you from A to B without the fumes. As electric vehicles become more common, understanding how these motors function can help us appreciate the shift towards greener transport. It’s a big change, and knowing how it all works is a step in the right direction.

Frequently Asked Questions

What is an electric motor and how does it work?

An electric motor converts electrical energy into mechanical energy using electromagnetic principles. It has two main parts: the stator, which is stationary, and the rotor, which spins.

How is an electric motor different from a traditional engine?

While both motors and engines create motion, an engine typically uses fuel combustion to generate energy, whereas an electric motor uses electricity.

What are the main parts of an electric car motor?

The key components include the stator, rotor, bearings, and thermal cooling systems. Each part plays a vital role in the motor’s function and efficiency.

What types of electric motors are used in cars?

Electric cars commonly use Direct Current (DC) motors and Alternating Current (AC) motors. Each type has its own advantages and applications.

How do electric vehicles recover energy while driving?

Electric vehicles use a system called regenerative braking, which captures energy during braking and sends it back to the battery for reuse.

What are the benefits of using electric motors in vehicles?

Electric motors are efficient, produce fewer emissions, and can be more cost-effective over time compared to traditional combustion engines.